Testing is available through our partnership with FLSmidth. Capabilities and Unit Operations at FLS Whitehall R&D include the following:

- Pyroprocessing:

- Rotary Systems (Kiln, Dryers)

- Gas Suspension System (Calciners, Dryers)

- Fluidized Beds (Dryers, Inert Bed)

- Packed Bed

- Combustion Chambers

- Crushing/Milling

- Ball and Vertical Mills

- Classifier

- Crushers (Jaw, Roll, “Abon”)

- Bond Testing (Ball, Abrasion, Impact)

- Chemical Assays

- Physical Properties

- Gaseous Emissions

Available Unit Operations

- 0.3m x 4.6m Rotary Kiln

- Refractory Lined

- Capacity: 15-35 kg/h

- 1450°C Maximum

- Solids Residence Time: 0.5-3 hours

- Fuel: gas, liquid, solid

- Adjustable Speed/Slope

- Onboard Air or Fuel Injection

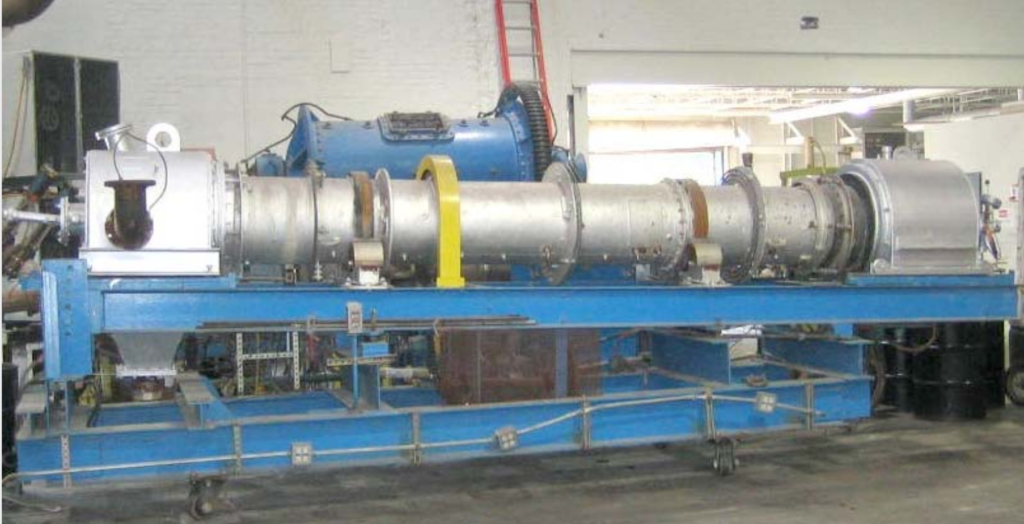

- 0.9m x 15.2m Rotary Kiln

- Refractory lined

- Capacity: 100-250 kg/h

- 1450°C maximum

- Solids residence time: 0.5-5 hours

- Fuel: gas, liquid, solid

- Adjustable speed

- Onboard air or fuel injection

- Sub- or super- stochiometric firing

- Precalciner & cyclone preheating

- Bag filter, wet scrubber, & ID fan

- 0.46m x 3.7m Rotary Dryer

- Stainless steel

- Capacity: 100-250 kg/h

- Maximum inlet temperature: 1200°C

- Solids residence time: 10-45 minutes

- Fuel: gas, liquid, solid

- Bag filter & ID fan

- 0.15m Flash Dryer

- Stainless steel

- Capacity: 25-100 kg/h

- Maximum gas outlet: 700°C

- Gas residence time: 0.5-1 seconds

- Collection cyclone

- Bag filter

- Fuel: gas, liquid, solid

- 0.3m x 1m Batch Rotary Kiln

- Refractory lined

- Capacity: 5-15 kg

- Maximum: 1450°C

- Fuel: gas

- Atmosphere: oxidizing or reducing

- Online sampling

- 0.075m Flash Calciner

- Stainless steel

- Capacity: 2-10 kg/h

- Maximum 1150°C

- Gas residence time: < 1 sec.

- Multi-stage fuel injection

- Fuel: Propane

- Bag filter & ID Fan

- 0.15m Flash Calciner

- Refractory Lined

- Capacity: 10-25 kg/h

- Maximum: 1550°C

- Gas residence time: 1.5-2.5 sec.

- Multistage fuel injection

- Fuel: gas, liquid, solid

- Collection cyclone, bag filter, & ID fan

- 0.35m 3-Stage Flash Calciner

- Refractory Lined

- 2 Preheat cyclones

- Capacity: 100-250 kg/h

- Maximum: 1450°C

- Gas residence time: <1.5s

- Multistage fuel injection

- Fuel: gas, liquid, solid

- Bag filter, wet scrubber, ID fan

- 0.61m Flash Calciner

- Refractory Lined

- Up to 3 preheat cyclones

- Capacity: 200-500 kg/h

- Maximum: 1450°C

- Gas residence time: < 1.5 sec.

- Multistage Fuel Injection

- Fuel: gas, liquid, solid

- Bag filter, wet scrubber, ID Fan

Material Preparation Unit Operations

- Packed Bed Preheater

- 1m x 1.5m Dry Grinding Ball Mill

- Single compartment

- Open- or closed-circuit operation

- Capacity: 100-300 kg/h

- Dynamic classifier

- Bag filter, ID fan

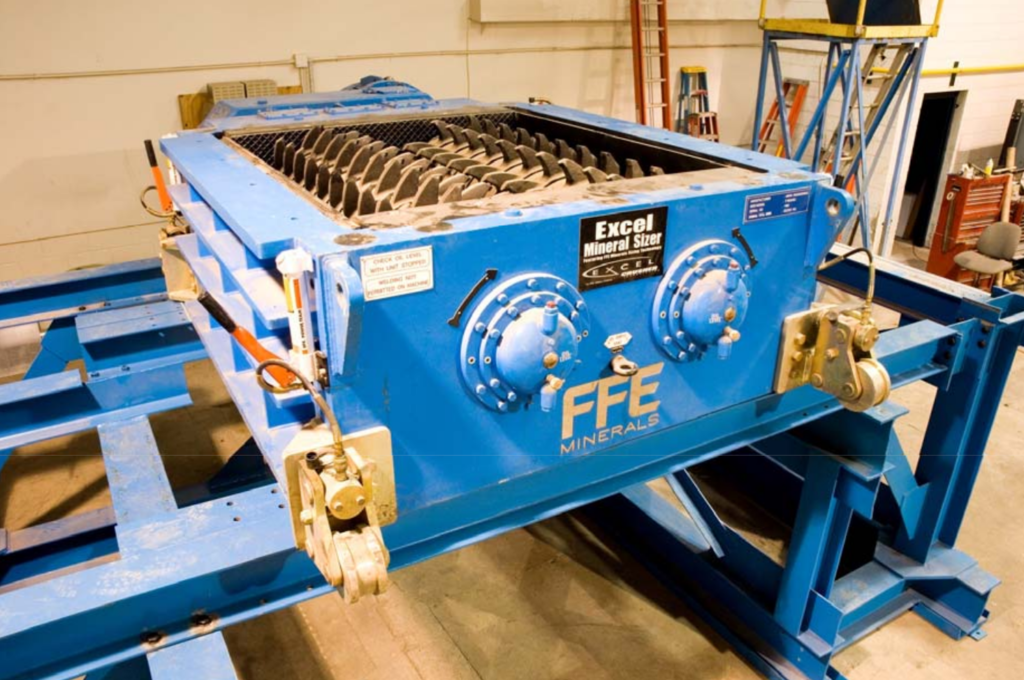

- Low-Speed Sizer (Abon)

- Hammer Mill Dryer

- Agglomeration

- Disc pellitizers

- 0.3m: 2-10 kg/h

- 1m: 25-100 kg/h

- Extruder

- 50-150 kg/h

- 5 die options

- Pin pelletizer

- 25-100 kg/h

- Disc pellitizers

Analytical/Laboratory

- Physical Analyses

- Bulk density

- Angle of repose (AOR)

- Specific gravity

- Moisture & drying rate

- Particle size: Sieve, “Air Jet”, & laser

- specific surface area (BET, Blaine)

- Lime hydration reactivity (ASTM & GOST)

- Limestone strength

- Bond ball mill grindability

- Bond crushability

- Unconfirmed compressive strength

- Abrasion index

- Furnace sticking tests

- Fluidization analysis

- Chemical Analyses

- Elemental

- Atomic Absorption

- X-Ray Fluorescence (fused bead, pressed pellet, or powder)

- Lithium acid and water solubility

- Vanadium water solubility

- Sulfur speciation and removal

- Organic and inorganic carbon

- Available CaO (ASTM & GOST)

- Nickel speciation

- Iron speciation

- Chrome metallization

- Total phosphorus and reactivity

- Laboratory emissions analysis (including FTIR)

- Elemental

- Lab Furnaces

- Tube furnaces (1250°C max.), 2x

- Muffle furnace (1200°C), programmable

- Fast heat-up furnace (1400°C max.), programmable

- Smelting furnace (1700°C max.)

- Electric rotary tube furnace (3-zone, 1450°C max.)