The wood products industry generates substantial amounts of saw and sander dust as part of normal operations. Utilization of wood as an alternative source of energy has been gaining interest since the last few years particularly in the pulp industry. Firing of 100% wood powder in rotary kilns has shown success elsewhere which means recycling of waste wood might be a source of fuel in the future. A Brazilian study has shown that when all expenses (installation, operation and fuel price) are considered, the breakdown of cost reduction would be as follows based on fuel oil: (i) fuel oil 100%; (ii) pulverized and dried wood 47% (iii) pulverized charcoal 68% which is worth the capital investment.

Alpha-Thermal Solution

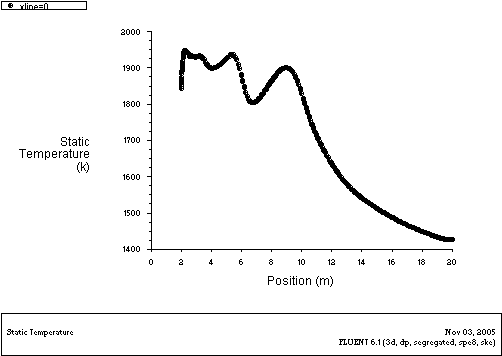

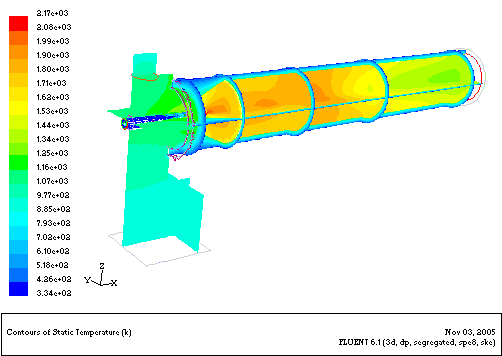

We designed a multi-channel burner to handle the co-firing of pulverized fuel with varying amount of biomass using CFD modeling. The model comprised various sub-models including (i) the initial heating of the particle, (ii) devolatilization of coke and biomass, (iii) char combustion, (iv) volatile combustion, and (v) NOx formation. Initial results showed bifurcation of biomass and coke flame profiles but this could be resolved with air flow optimization.