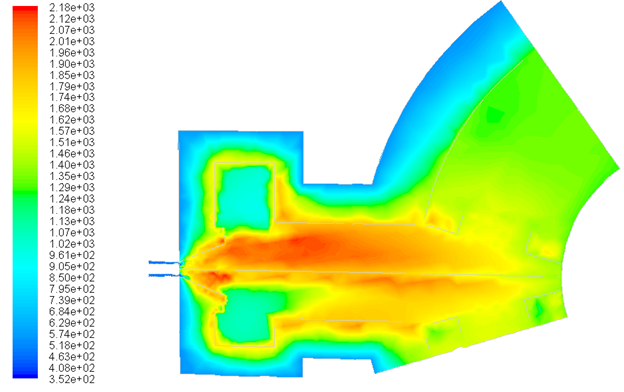

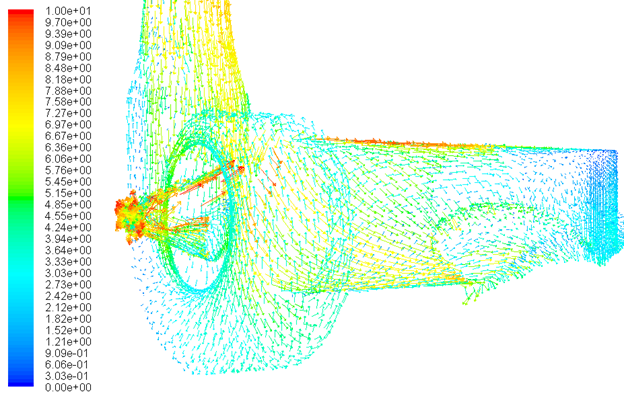

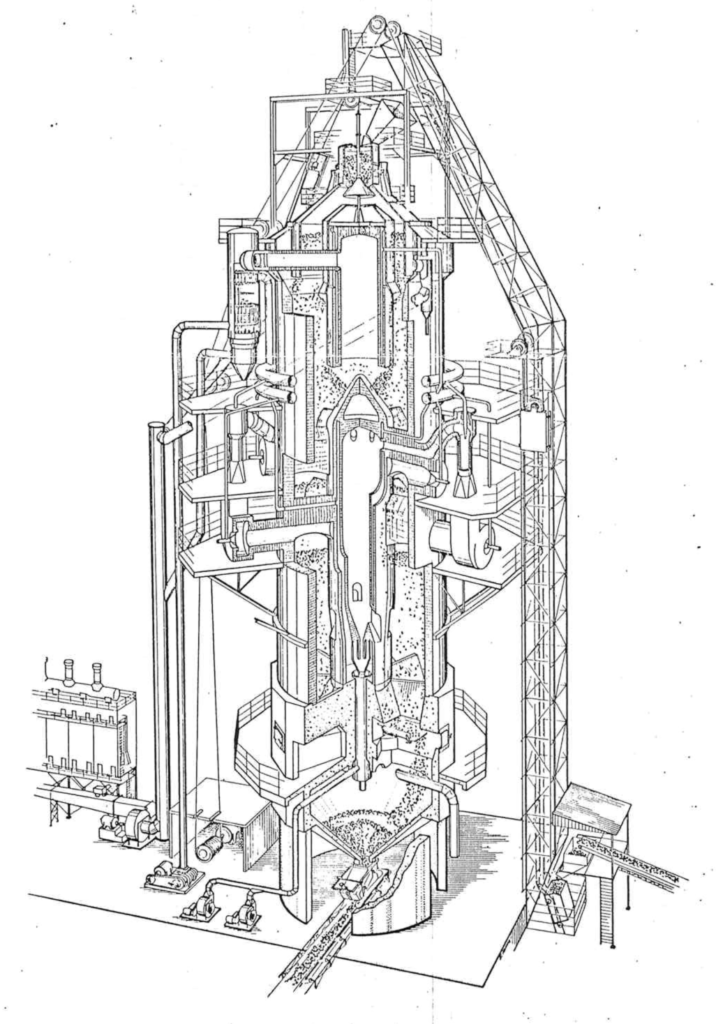

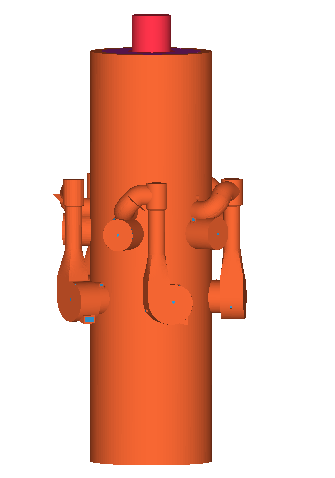

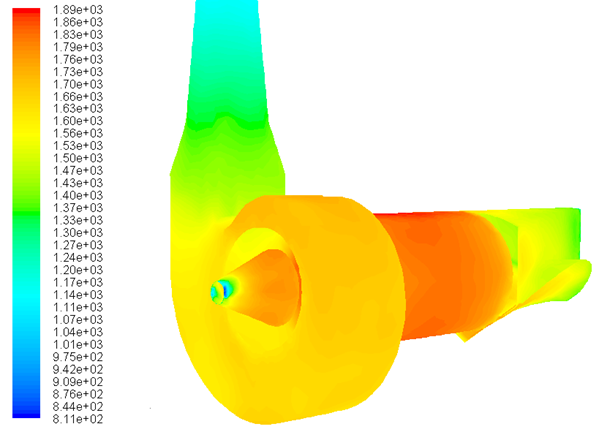

Annular shaft kiln (ASK) with five burners at each top and bottom levels (total of 10 burners). Our CFD analysis reveal flow and temperature imbalances which were corrected to optimize fuel efficiency, improve temperature distribution and product quality as a result.

of about 1890K